Product categories

- PRODUCT DETAILS

- TECHNICAL SPECIFICATION

- APPLICATION PROJECT

Operating Handbook:This equipment use positive and negative pressure to test the seal performance, it is suitable for all kinds of bottle, tube, tank, boxes of the security,medicine,medical devices,household appliance,electronic components,automobile ,LED etc and other sealing test, It can be used for the drop pressure test after the specimen seal performance test.

Major Characteristic:

1. Use the electronics to keep pressure, digital display, instantly and exactly.

2. Use the precision pneumatic components, superior sealing performance.

3. Fit precision pressure regulating valve, the pressure can be adjusted randomly.

4. Electronic pressure switch, easy to operating, long dwell time.

5. Fit timer inside, dwell time is clear at a glance and it can be set randomly.

Specification of the equipment:

|

Product Name |

Seal test machine |

|

1、Components of equipment |

|

|

Body of machine |

Use SUS304 stainless steel trigger |

|

ECS |

Adopt PLC |

|

Tested time |

Set by timer,Range:1-9999S、1-9999M、1-9999H。 |

|

Pressure |

-0.06-0.5 MPa(Standard)。 |

|

Appearance dimension |

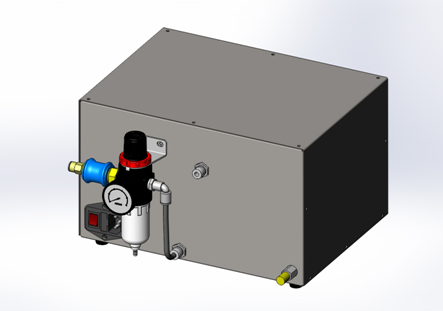

305mm(L)×345mm(B)×195mm(H) |

|

Power supply |

Single phase AC220V 50Hz。 |

|

Air-supply pressure |

0.6 MPa(Prepared by yourself)。 |

|

Air connection |

TUΦ6 |

|

Net |

About 5kg |

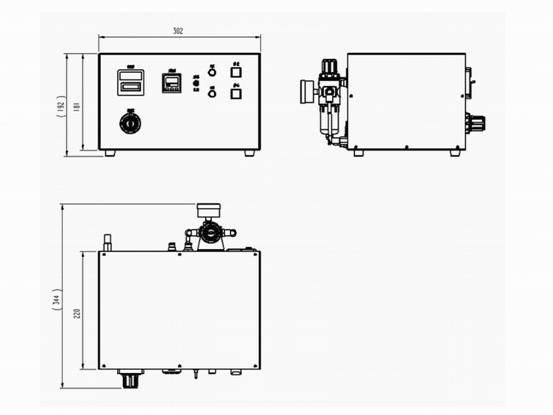

2、Physical dimension:

Notice: this dimension is an approximate valve.

Operating

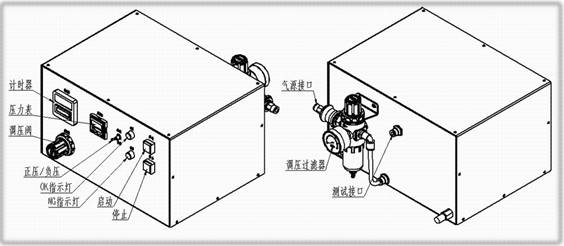

1、Description of components

“Start”:Press the“start”button, device start to run.

“Stop”: During the running time, press the“stop”button, running is end.

During the equipment standby, press the ”stop” button, the equipment for pressure relief operation, the internal pressure is emptying, and external pressure is equal.

Notice: Please don’t press the“stop”button continuously, because it needs 5sec to finish a standby.

“OK”: When the internal pressure is above the setting pressure, theindicator light of

“OK”is lighting.“NG”:When the internal pressure is below the setting pressure, the indicator light of

“NG”is lighting.“Positive pressure/negative pressure”: when the switch is pointing to the“positivepressure”, press the”start”button, the device start the“positive pressure”and beginto test.When the switch is pointing to the“negative pressure”button, press the“start”button, the device start the“positive pressure”and begin to test.

“Piezometer”: display the current pressure, set the test pressure, more operating details please refer to the operating handbook.“Pressure regulating valve”:During the“positive pressure”test pattern, use for adjusting the test pressure.“Timer”:displayed time, set the test time, more details please refer to the operating handbook.“Test interface”: used for connecting products to be tested.“FR”: used for regulating the air source pressure, filter the impurity of compressed air. When the equipment is on the“negative pressure”test pattern, regulate the“FR”, the negative pressure can be changed; the high air supply pressure leads high negative pressure, the low air supply pressure leads low negative pressure.

“Air connection”: connect the air source, supply air.

2、Use of the equipment.

1> Connect the device power plug and relevant outlet at first, it must need the reliable ground protection; then make the compressed air which meets the requirement through to the air connection; at last, connect the product and the test interface with air pipe.

2> According to the technical requirement of products to be tested, equipment needs to undertake following adjustment:

A. Choose the test mode as it needs: positive pressure and negative pressure.

B. Set and adjust the test pressure; the displayed pressure needs to be higher about 5% more than the set pressure due to the barometric fluctuation.

C. Set the test time.

3> Press the“start”button, the device start to run. When the internal pressure of products reach to the set pressure, begin to time, in the pressure test, after reach to the set time:

The“OK”indicator light will be on if the internal pressure is onto the set pressure;

The“NG”indicator light will be on if the internal pressure is below the set pressure;

Then the device start to release relief automatically, empty the internal pressure of the part.

4> Pull out the air pipe connection from the tested product, the test has been finished.

3、Troubleshooting

1.When the equipment can’t operate as normal in the current test mode.

Please turn to the other test mode at first, then start to the device, if it can work as normal; then run back to the fault test mode and start to run the device;

If it doesn’t work properly, please turn off the power, turn on the power again after 5seconds.

2.The device begin to run, if the display pressure always can’t reach to the set pressure or more higher than the set pressure.

“Positive pressure”test mode: check the”FR”at first; If there is no problem, then check the“pressure regulating valve”, then according to the need to adjust.

“Negative pressure”test mode: Check the“FR”, according to the need to adjust.

If any inquiry, Pls contact Sunny:8613620020030, TKS!

NEXT:The second generation Seal test machine